產品介紹 performance introduction

SHG系列是2015年黑龍江艾爾機械制造有限公司結合木業、地板表板、家居面板、立刨等行業設計的一款表板烘干機。

該機型主要用于烘干名貴的天然家具用木皮,刨切木皮,實木復合地板的表板等。采用了非常昂貴且網孔很密的不銹鋼網帶干燥單板,單板表面無痕跡、污點。配置方面上采用日本三菱變頻、瑞典ABB電機、英國斯派莎克疏水閥等國內外優質配件確保產品品質。結構上采用了單板輸送呈S型干燥法,并使木皮在反復彎曲后消除內應力,使之烘干出來的單板平整度、光潔度達到理想效果。采用風壓式氣流循環系統,頂式離心風機,具有高風壓,大風量之特性,散熱器為鋼鋁復合式結構,具有散熱面積大且傳熱效果佳的特點。采用橫向循環垂直噴氣方式,噴射的氣流能高速均勻有效地作用于單板表面。采用了烘干室高低溫區分開控制的方式,根據單板的種類、厚度、和含水狀況的不同可自由選擇干燥速度和加熱溫度。本機型采用烘干區與冷卻區網帶斷開式,中間部分采用毛刷輥過渡,從而大幅度的減少加熱區熱耗以及冷卻能耗。

該機型可與多種熱源配套:蒸汽鍋爐、導熱油鍋爐、及熱風爐、燃氣鍋爐等

熱源安裝形式:1.下吸式 2.上吸式 備注:1.配用蒸汽鍋爐,導熱油爐時,熱源安裝形式為下吸式安裝,烘干機內配有多組SRZ.SRL系列熱源交換散熱器.但訂制烘干機時,蒸汽鍋爐,導熱油爐等鍋爐有客戶自行訂制,我公司不配置鍋爐。 2.配用熱風爐時,公司自配用該機型專用的“ARRFL型熱風爐”,同時熱源安裝形式為“上吸式”。 Characteristics: Expensive stainless mesh-belt with dense mesh has been adopted to dry veneers and make them tidy and clean on surface."S”type transportation in this dryer ensures required planeness and degree of finish on veneers.Air circulation system of wind pressure style and centrifugal blowers which have been mounted on top have been used.High wind pressure and large air volume can be reached.Radiator is made of steel and aluminum which has the advantage of good heat conduction and large radiating area..The air flow acts on the veneers evenly by ways of circulating horizontally and sprayed vertically.Optional drying speed and heating temperature according to the thickness and moisture content of veneers is available by the individual controls on high-temperature and low-temperature areas.Equipped with Mitsubishi branded inverter,ABB motors and SpiraxSarco steam trap,this veneer dryer enjoys high performance.Drying area and cooling area are connected by brush roller instead of mesh-belt which will save more energy on both heating and cooling

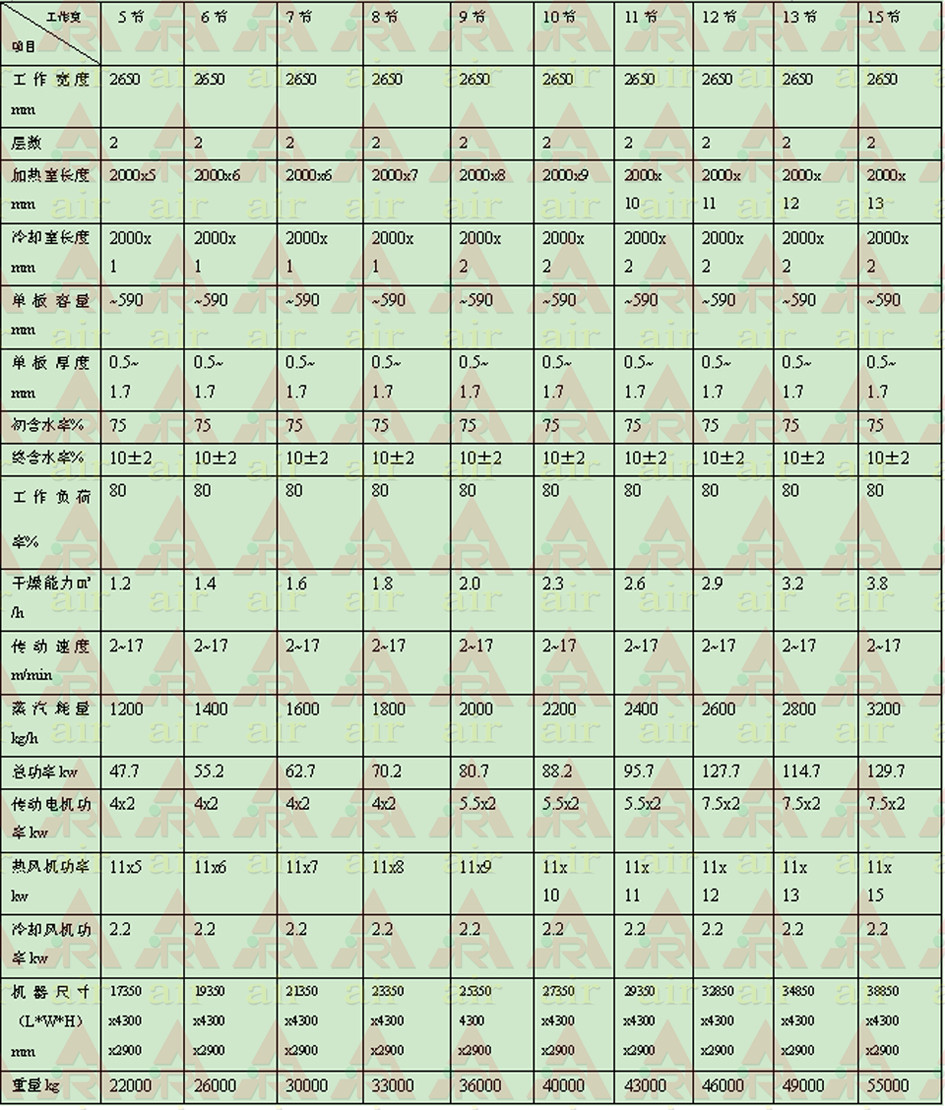

主要規格及技術參數

工作負荷率% 85 外形尺寸: 長x寬x高mm(23200~28200)x(5200~6650)x4700.

|